How to Measure a Pallet (And Why Most People Get It Wrong)

Measuring a pallet seems simple at first glance. Grab a tape measure, jot down a few numbers, and move on — right?

In reality, pallet measurement is one of the most commonly misunderstood steps in logistics and supply chain operations.

Incorrect pallet measurements can lead to inaccurate quotes, freight reclassification, rejected shipments, racking incompatibility, automation failures, and unnecessary costs. And more often than not, these issues trace back to a straightforward problem: pallets weren’t measured correctly.

This guide explains how to measure a pallet correctly, shows where most people go wrong, and demonstrates why getting it right matters more than you might think.

Why Accurate Pallet Measurement Matters

Pallet dimensions are foundational to nearly every downstream logistics decision. When measurements are off by even an inch, the ripple effects can be significant.

Accurate pallet measurements help ensure:

Correct freight pricing and classification

Proper warehouse racking and storage compatibility

Smooth interaction with conveyors, forklifts, and automation systems

Accurate pallet quotes and material planning

Reduced risk of damaged goods or rejected deliveries

In short, pallet measurement isn’t just a technical detail; it’s a cost, safety, and efficiency issue.

What is The Industry Standard for Measuring a Pallet?

Before diving into how to measure a pallet, it’s essential to understand how measurements are universally communicated in the pallet industry.

Pallet dimensions are always expressed in the following order:

Length × Width × Height

This order is not optional.

Swapping length and width — a very common mistake — can result in confusion, incorrect pallet builds, or misaligned expectations between suppliers, carriers, and warehouses.

For example, a standard GMA pallet is measured as 48 inches (length) × 40 inches (width) — not the other way around.

How to Measure a Pallet (the Right Way)

Measuring a pallet correctly requires more than eyeballing deck boards or estimating height. Each dimension should be measured deliberately and consistently.

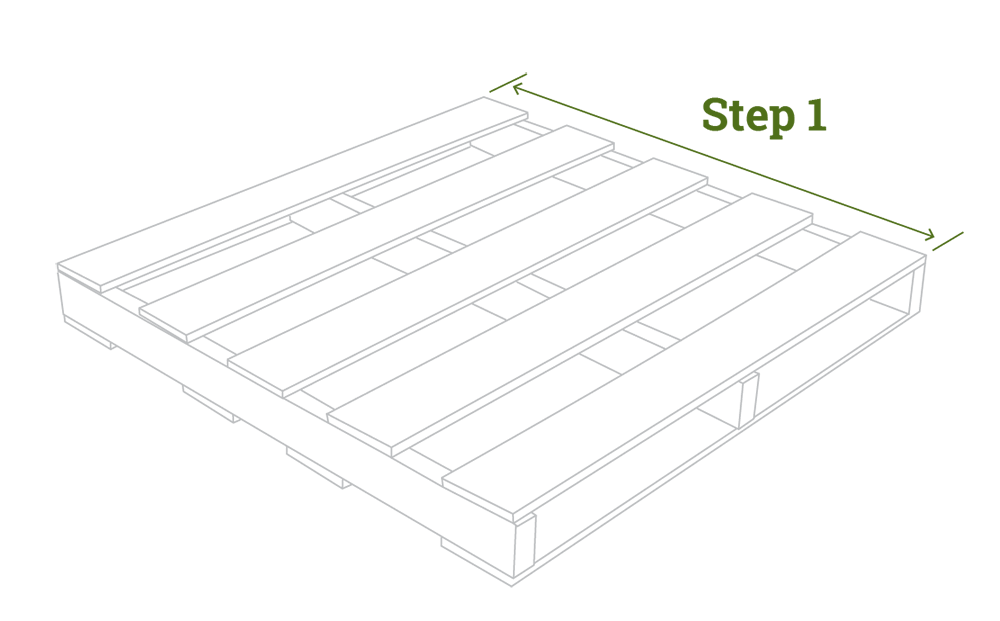

Step 1: Measure the Pallet Length

The length is the longest side of the pallet’s top deck.

Measure from the outermost edge of one deck board to the outermost edge of the opposite side. Be sure to include any deck board overhang — measuring only the stringers or blocks underneath is a common mistake.

If the pallet has been repaired or modified, confirm that no boards extend beyond the original footprint.

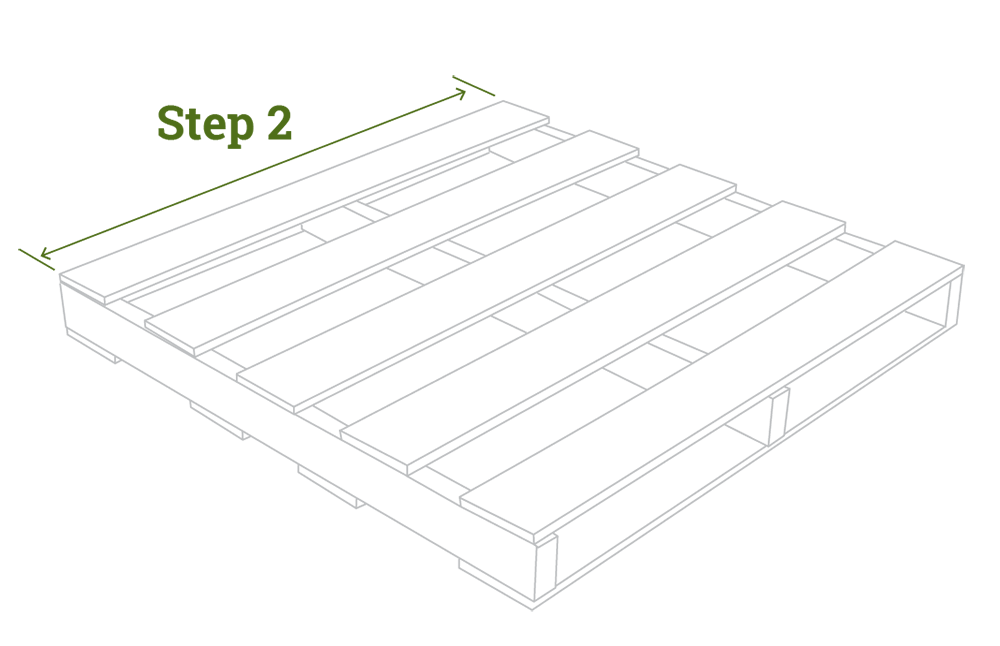

Step 2: Measure the Pallet Width

The width is the shorter side of the pallet’s top deck.

As with length, measure edge-to-edge across the full deck surface. Even small protrusions matter, especially for automated systems, racking, or tight trailer loading.

Consistency is key — always measure width the same way across pallets to avoid discrepancies.

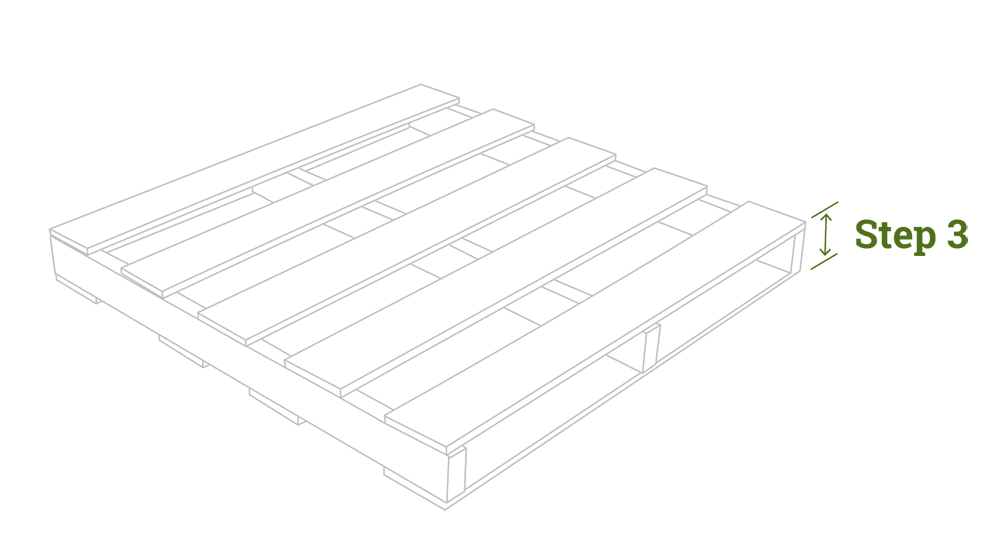

Step 3: Measure the Pallet Height

The height is measured from the very bottom of the pallet to the top of the deck boards.

This is the dimension most frequently overlooked — and one of the most important.

Pallet height affects:

Forklift tine clearance

Conveyor and automation compatibility

Stack height and storage planning

Freight cube calculations

Height varies depending on pallet type. Stringer pallets and block pallets often have different heights, even if their length and width are the same.

5 Common Pallet Measurement Mistakes to Avoid

Even experienced operators make pallet measurement errors. The most common ones include:

Measuring only length and width, while ignoring height

Reversing length and width in documentation

Measuring damaged or warped pallets instead of serviceable ones

Rounding dimensions instead of using exact measurements

Measuring the unit load instead of the pallet itself

These mistakes may seem minor, but they can compound into real operational problems.

Measuring an Empty Pallet vs. a Loaded Pallet

Another frequent source of confusion is the difference between pallet dimensions and unit load dimensions.

A pallet’s measurements describe the platform itself. A unit load includes the pallet plus the product stacked on it (think boxes, shrink wrap, corner boards, and all).

Both measurements are important, but they serve different purposes:

Pallet measurements are used for sourcing, repair, racking, and automation

Unit load measurements are used for freight pricing, trailer optimization, and storage planning

Mixing the two can lead to incorrect quotes and misaligned expectations.

How Pallet Measurement Impacts Cost, Storage, and Design

Accurate pallet measurements influence more than just paperwork.

From a cost perspective, dimensions determine how much lumber or other materials are required to build the pallet. From a logistics standpoint, they affect how many pallets fit in a truck, how they sit in racking, and how they move through material handling systems.

Measurement accuracy also plays a critical role in:

Custom pallet design

Pallet repair and recovery decisions

Export compliance and heat-treatment requirements

Long-term pallet management strategies

When pallets are measured correctly from the start, operations run more smoothly across the board.

When to Get Help Measuring Your Pallets

There are situations where professional support is especially valuable, including:

Custom pallet programs

Automated or high-bay warehouse environments

Export shipments with compliance requirements

Operations experiencing pallet failures or inefficiencies

A pallet expert can evaluate your current pallets, confirm accurate measurements, and identify opportunities to improve performance and reduce costs.

Not Sure What Pallet Size You Actually Need? We Can Help.

If you’re unsure whether your pallets are sized correctly—or if you’ve ever questioned whether your current pallet setup is truly working for your operation—you’re not alone. Many companies rely on “what they’ve always used” without realizing that a small change in pallet size, design, or height could improve efficiency, reduce damage, or lower costs.

At Olympic Forest Products, we work with customers every day to evaluate pallet dimensions, understand unit loads, and determine whether standard pallets are the right fit or if a custom solution would perform better. Our team looks beyond length and width to consider how pallets move through your warehouse, interact with handling equipment, and support your products from origin to destination.

If you don’t know the correct pallet size for your operation or just want a second set of expert eyes, reach out to Olympic Forest Products.

We’re here to help you get it right.