What Is a GMA Pallet?

A GMA pallet is the most widely used pallet standard in the United States, originally developed by the Grocery Manufacturers Association to promote uniformity and efficiency in the fast-moving consumer goods industry.

By standardizing core dimensions and construction, the GMA pallet helps manufacturers, distributors, and retailers move products quickly and safely through warehousing, transportation, and store delivery.

Today, its influence stretches far beyond grocery – e-commerce, food & beverage, consumer packaged goods, and general manufacturing, all rely on the GMA pallet spec because it integrates seamlessly with racking, conveyors, forklifts, and automated systems across the country.

Standard Specifications of a GMA Pallet

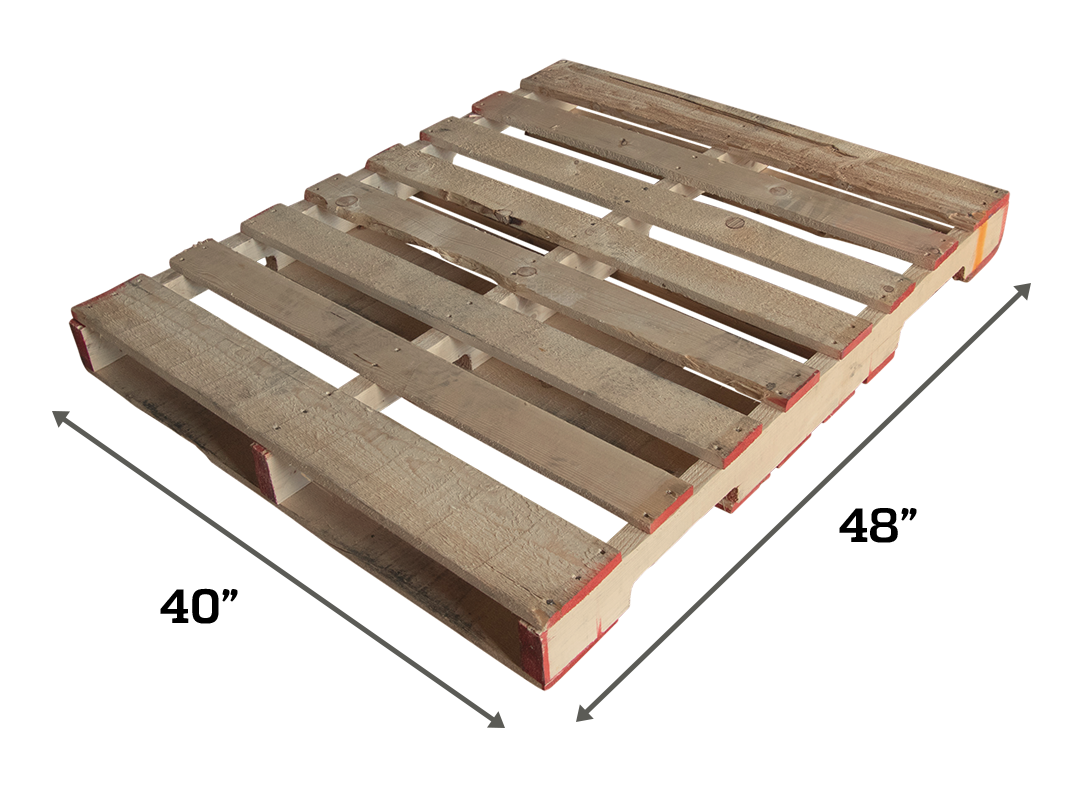

At its core, a GMA pallet measures 48 inches by 40 inches, with a footprint optimized to fit trailers and common racking and material-handling equipment.

What Are GMA Pallets Made Of?

GMA pallets are commonly built from hardwood or softwood lumber, and many are constructed from recycled components to support circular economy goals. Designed for both manual and automated environments, a properly built GMA pallet supports substantial dynamic loads while maintaining consistent performance in forklifts, pallet jacks, stretch-wrap stations, and conveyor systems.

Most GMA pallets use a stringer design featuring three parallel stringers, with a typical deck board layout of seven top deck boards and five bottom deck boards—a balance that provides strength, stability, and smooth handling while maintaining cost efficiency.

What are GMA Pallets Used For?

GMA pallets are the backbone of modern U.S. logistics, supporting nearly every major supply chain from grocery distribution to e-commerce fulfillment. Because they’re standardized, durable, and compatible with nearly all warehouse and transport systems, GMA pallets make it easier for businesses to move high volumes of products safely and efficiently.

In the grocery and consumer packaged goods (CPG) industries, GMA pallets facilitate the swift movement of food, beverages, and household items from manufacturers to distribution centers and retail shelves. Their uniform 48x40 design makes them ideal for automated palletizers, conveyor lines, and shrink-wrapping systems commonly used in high-speed production environments.

What Industries Rely on GMA Pallets?

Beyond grocery, manufacturers and distributors in sectors such as pharmaceuticals, automotive parts, and home improvement rely on GMA pallets to standardize their material handling and shipping processes. The consistent size and strength of these pallets help companies maximize trailer space, reduce damage during transit, and simplify cross-docking at regional distribution hubs.

Because GMA pallets are so widely accepted, they’re also a staple in third-party logistics (3PL) and retail warehouse operations, where interchangeability and cost efficiency are key. Whether you’re shipping paper goods, frozen foods, or packaged electronics, the GMA pallet serves as a reliable, industry-approved platform that keeps goods—and business—moving.

Why GMA Pallets Became the Industry Standard

The GMA pallet specification solved a long-standing problem in North American logistics: incompatibility.

Before its adoption, pallet sizes varied significantly, resulting in bottlenecks in storage, transportation, and handling. The GMA pallet created a uniform platform that streamlined cross-industry collaboration. Carriers could plan loads more accurately, racking suppliers could standardize beam lengths and load ratings, and warehouses could standardize slotting and automation. Uniformity also reduced product damage by improving load stability and predictable handling clearances.

Just as importantly, the GMA footprint aligns with shrink-wrapping, case-picking, and conveyor technologies, enabling higher throughput and safer operations in high-volume facilities.

5 Key Benefits of Using GMA Pallets

Because the GMA pallet is the gold standard for pallets, its use simplifies a lot of things for companies. GMA pallets are:

Universally Accepted: The standardized size and design of GMA pallets make them compatible across nearly all U.S. warehouses, carriers, and retailers.

Cost-Effective: High production volume and widespread availability keep costs low for both new and recycled pallets.

Easy to Maintain: Readily available parts and repair services extend pallet life and reduce replacement expenses.

Efficient: Standardization streamlines procurement, shipping, and receiving while minimizing the risk of rejected loads.

The Sustainable Choice: GMA pallets can be repaired, reused, and ultimately recycled—supporting waste reduction and circular economy goals.

“When customers ask for a dependable, widely compatible option, the GMA pallet is almost always our starting point. It’s the sweet spot of availability, price, and performance—and it works across 99% of the environments our clients run.”

Is the GMA Pallet Right For My Business?

For most U.S. applications, the GMA pallet is the fastest path to efficiency, as it integrates seamlessly with standard racking, automation, and transportation systems.

That said, some operations benefit from alternatives.

Block pallets may be preferred for heavier loads, four-way entry from any side, or specific automation interfaces.

Custom pallets can optimize cube utilization, improve load stability for unique products, or address specialized sanitation or handling needs.

If you’re unsure which direction to take, we can help you evaluate your current unit loads, handling equipment, and racking to determine whether a standard GMA pallet will meet your goals—or whether a block or custom design would deliver better performance and return on investment.

How Olympic Forest Products Supports GMA Pallet Supply

Olympic Forest Products maintains dependable GMA pallet availability through five family-owned mills and a national network of manufacturing partners. That footprint allows us to meet regional demand efficiently, stabilize lead times, and tailor specs to your load profile and racking environment.

Beyond supply, we offer pallet management programs that right-size on-hand inventory, repair and recovery services that extend pallet life, and recycling solutions that divert damaged units from landfills. If you export, our team can supply heat-treated GMA pallets to support ISPM-15 compliance while maintaining the same handling advantages you expect domestically.

Looking to standardize on GMA pallets—or decide if they’re the right fit? Contact Olympic Forest Products to speak with a pallet specialist and get a tailored recommendation for your operation.