What Are Block Pallets?

Block pallets are designed for strength, stability, and ease of handling, making them one of the most versatile and durable pallet types available. Unlike traditional stringer pallets, which use parallel boards for support, block pallets are built with nine solid blocks (one in each corner, one in the center of each side, and one in the middle) that provide a sturdier foundation and allow for four-way forklift access.

This design enhances load distribution, making block pallets an ideal choice for industries that rely on automation, handle heavy loads, or experience frequent handling, such as manufacturing, food & beverage, and retail distribution.

“Block pallets offer the best of both worlds—durability and accessibility. They’re built to last, and they move easily through modern supply chains where efficiency and safety are critical.”

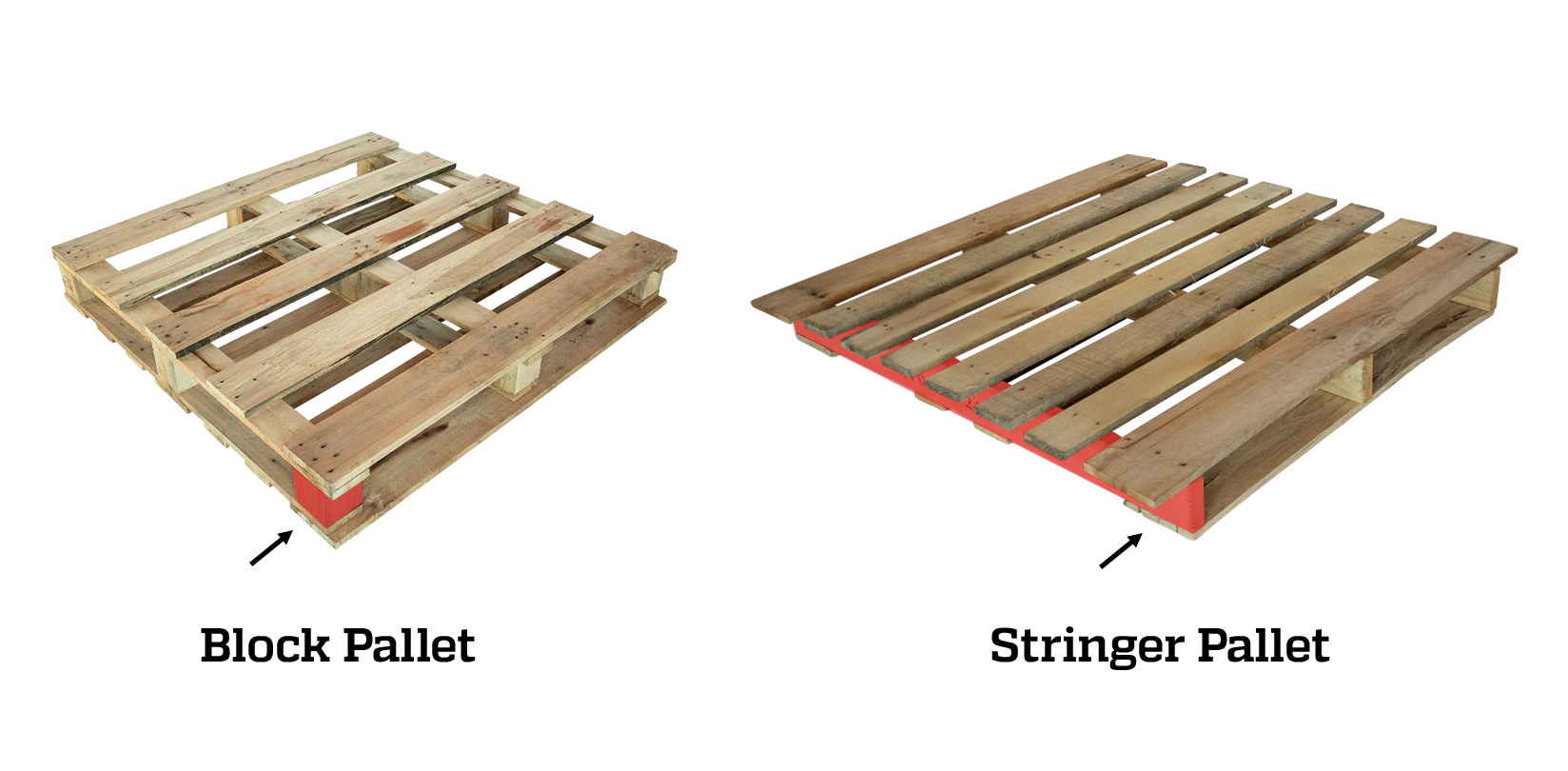

How Block Pallets Differ from Stringer Pallets

The primary difference between block pallets and stringer pallets lies in their structural design. While stringer pallets use two or three long boards (stringers) for support, block pallets use blocks of wood, plastic, or metal placed throughout the pallet base.

This structural difference gives block pallets several advantages:

Four-way entry: Forklifts and pallet jacks can lift from any side, improving efficiency in busy warehouses.

Stronger design: The block construction offers improved weight distribution and enhanced load stability.

Increased longevity: With more contact points and greater rigidity, block pallets are more resistant to damage over time.

What Are Block Pallets Used For?

Block pallets are also commonly used in European supply chains, where the Euro pallet (1200 x 800 mm) follows similar design principles—highlighting their global appeal for standardized, heavy-duty logistics.

Common Materials Used in Block Pallets

Block pallets can be built from several materials, depending on the industry and intended use:

Wood: The most common option, offering a balance of strength, repairability, and cost-effectiveness.

Plastic: Lightweight, hygienic, and resistant to moisture or contaminants—ideal for food, pharmaceutical, and export applications.

Metal: Used for extreme durability and heavy industrial loads, often in long-term storage or closed-loop systems.

Each material has its place in modern logistics. For example, a food manufacturer might use plastic block pallets for hygiene and washability, while a construction supplier might choose hardwood block pallets for maximum durability and weight capacity.

5 Key Advantages of Using Block Pallets

Block pallets are the go-to choice when reliability, longevity, and versatility are most important. Their key benefits include:

Superior Strength: Built to handle heavier loads and repeated use without warping or cracking.

Efficiency in Handling: Four-way entry simplifies forklift operation and warehouse organization.

Long-Term Value: While typically more expensive upfront, block pallets last longer and often cost less per trip over time.

Automation Compatibility: Their consistent dimensions and strength make them ideal for automated warehouses and racking systems.

Sustainability Options: Available in recycled wood or plastic and can be repaired, reused, or recycled.

6 Industries That Rely on Block Pallets

Block pallets are a staple across industries that demand durability, consistency, and efficiency in material handling. Their four-way entry design and superior strength make them the preferred choice in environments that rely on automation, frequent handling, or heavy loads.

1. Manufacturing and Industrial Operations

From automotive parts to machinery components, manufacturers rely on block pallets for their ability to support heavy, irregularly shaped loads. The reinforced block design provides the stability needed for secure storage and transport—especially in plants using automated palletizers or robotic systems.

2. Food and Beverage Distribution

The food and beverage industry depends on clean, durable pallets that can handle frequent rotation through warehouses, cold storage, and retail distribution. Block pallets—particularly those made from heat-treated wood or plastic—are ideal for these high-volume, regulated environments because they are strong, reusable, and easy to sanitize.

3. Retail and E-Commerce Fulfillment

In retail and e-commerce, speed and standardization are key. Block pallets’ four-way access and compatibility with automated conveyors make them ideal for fast-moving fulfillment centers and distribution hubs, reducing downtime and improving handling efficiency.

4. Pharmaceuticals and Healthcare

Precision and cleanliness are essential in healthcare logistics. Plastic block pallets are often used to transport medical supplies, pharmaceuticals, and diagnostic equipment due to their resistance to contamination and compliance with FDA and ISPM-15 standards.

5. Construction and Building Materials

For heavy materials like cement, bricks, or lumber, block pallets provide the strength and structural integrity needed to handle significant weight. Their stability minimizes the risk of shifting or collapsing during transit to and from job sites.

6. Global Export and Logistics

Because block pallets are compatible with international standards—including Euro-style pallets—they’re a top choice for exporters managing complex, cross-border supply chains. Their design ensures smooth handling in ports, warehouses, and intermodal systems worldwide.

Whether used to move groceries, pharmaceuticals, or industrial components, block pallets deliver the reliability and consistency that keep supply chains running efficiently from origin to destination.

Olympic Forest Products Supports Block Pallet Design

At Olympic Forest Products, we manufacture and distribute high-quality block pallets designed to perform under the most demanding conditions. Our national network of suppliers and five family-owned mills allows us to deliver consistent, durable block pallets that meet your exact load, handling, and racking requirements.

Beyond manufacturing, Olympic provides pallet repair and recovery services, custom pallet design, and sustainability consulting to help customers get the most from every pallet. Whether you’re looking to upgrade to block pallets or improve your current supply chain efficiency, our team can help you evaluate options that balance cost, performance, and environmental goals.

Looking to incorporate block pallets into your operation? Contact Olympic Forest Products to discuss your material handling needs and find the best pallet solution for your business.